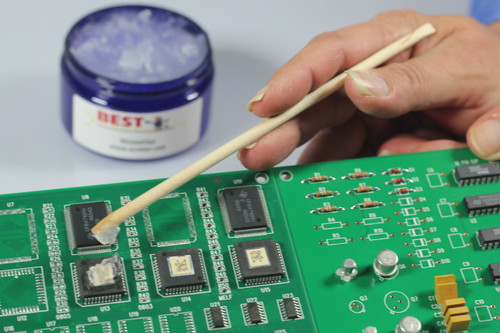

This is a unique stenciling BTC (QFN , LGS, etc) rework stencil system. It improves first pass yields and allows you to rework leadless devices without high-end rework systems.

This configurable part number means you do not have to sort through all of the patterns listed (there are many more).

The data you send us to make your part must have:

Pattern of the solder array incl dimensions

This BTC rework stenciling system allows you to manually place BTCs for prototyping or low volume builds.

The BTC rework stencils come in 0.004" thick.

- Minimum Aperture Size: .002in (.05mm)

- Stencil Material: .Plastic film with release liner. Adhesive is an acrylic hgih temperature-rated type of adhesive.

- Minimum Pitch: .020in (0.3mm)

- Maximum Stencil Size: Approx 4 x 4in (100mm x 100mm)

We accept either standard GERBER files, part data sheets or CAD files.

StencilMate(TM) stencils are packaged in groups of (10) pieces for either the part or board.

23 Reviews Hide Reviews Show Reviews

-

Nice and easy to use

Simple means to replace a QFN. Will keep using.

-

LGA Stencil

This really helped with a challenging 0.5mm pitch device. Rework was much more doable!

-

Simple Process

Wish I would have seen this product before. It is a the best way I have seen to replace LGAs

-

Worked like the Youtube video

Pretty easy to use . Hardest part is my old eyes seeing the tiny pads for alignment. Otherwise simples process

-

Good way to put LGAs back down

Rework is a pain for LGAs. This was a nice way to fix the issue.

-

Nice Product

It took a few times to get the hang of "bumping" but we finally did it. Thanks for talking me through the proces. I actually got talk to a real person

-

Stencils for QFNs

Took a while to get used to the process. However after a few of them I can see definate pluses to this technique

-

Thanks you

Product and order was perfect!

-

Fast and Easy

From the time I sent the drawing in until the product was here was within a week. This makes the proto assembly process a lot easier than trying to us hot air and a syringe of solder