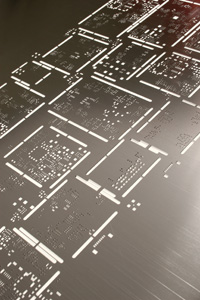

SMT stencils for PCB assembly feature fine pitch apertures cut on a high precision laser, smooth aperture walls for consistent and clean solder paste release and need to be designed, built and shipped rapidly.

Advantages to the Laser Cut SMT Stencil

There are numerous advantages to the laser cut SMT stencil.

- Smooth internal pad walls, with wall geometric changes less than 3μm for superior paste release characteristics

- Aperture consistency for a reduction in potential defects

- High pad positional accuracy for extreme fine pitch accuracy in printing. Tolerances of 5um are achievable with modern lasers

- Stencil to PCB registration, unlike chemically etched stencils, feature fine board to stencil registration

- Ultra fine-pitch patterns less than 250μm can be realized without problems allowing you to print today's challenging very fine pitch devices

BEST uses a high nickel content metal as standard for its SMT stencil production. PHD high nickel content stainless steel us used as standard has greater strength and smaller surface grain structures than other stainless steels, producing a smoother wall with better release characteristics. This results in a consistently higher performing printing process.

Lastly BEST knows what it takes to get projects done in a timely fashion. Its PCB rework and repair division and PCB rework tools division are under pressure to get projects shipped out quickly and accurately.

BEST can deliver a variety of stencils including framed stencils, framless stencils or SMT prototype stencils.

In order to get the best SMT stencil call BEST at (847) 797-9250.

847-797-9250

847-797-9250