IPC-A-610 Certification: Various Classes

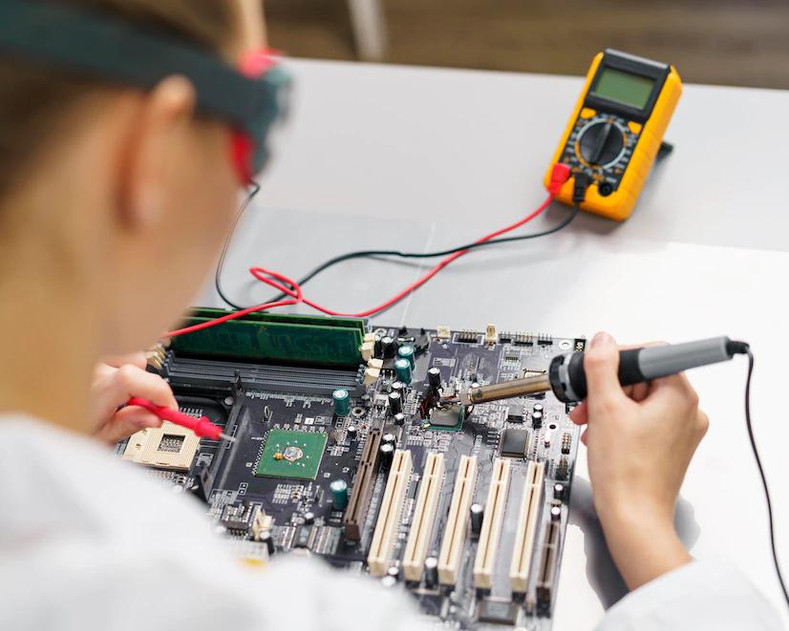

If you want to prove that you're up to par with the standards of the electronics industry when soldering circuit boards, being certified in compliance with the IPC-A-610 standard digital is a great way to do it. Obtaining the proper certifications helps show clients and companies that you are committed to producing high-quality electronic assemblies in accordance with industry standards.

Numerous considerations are made during the manufacturing of electronic devices, including the product's aesthetics and its capacity to sustain reliability over time. Every aspect of this can be viewed as either extremely positive or terrible or somewhere in between. There are three primary groups within the IPC-A-610 standard, each with its own unique set of capabilities and characteristics:

● Class 1

Given its location at the end of the manufacturing process, this phase of electronic assembling is the most lenient in terms of defects. This market category is typically dominated by low-priced products with low impact, such as children's toys.

Their succinct nature limits their usefulness, despite the fact that they are intended to deliver as promised. Due to the superior quality of the parts used in their manufacturing, the prices of Class 1 electrical devices are reasonable.

● Class 2

This IPC standard family is highly sought after for use with non-critical electrical components. Since these products may not be top-shelf, but they are guaranteed to last longer and be more productive, they are favored. This class is similar to the one before it in that it allows for a certain amount of flaws, such as the use of "off-pad" parts that perform normally but don't seem quite right.

● Class 3

To be designated as Class 3, electronic component assemblies must excel in all respects, including quality, reliability, and safety. Class 3 standards are so rigorous that many high-end electronic goods and other important assemblies must adhere to them.

It's hardly shocking that a higher-quality assembly would cost more. Developing a product with meticulously organized parts requires more effort and money.

Who should obtain IPC-A-610 accreditation?

The IPC-A-610 certification is the route to go if you want to demonstrate your competence in electronics assembly and soldering, whether it be in pursuit of the CIS or a teaching position, or simply for your own personal satisfaction.

Suppose you're responsible for assuring the quality and longevity of electronic assemblies. In that case, you should absolutely get your hands on an IPC-A-610 certification, since this will prove that the work you and others do is consistent with global PCB assembly standards.

Obtaining an IPC certification demonstrates your knowledge and skill with the material covered in the course. Certification must be renewed every two years; however, there is a 90-day grace period after the end of the accreditation term in which to do so. Therefore, it is highly recommended that both newcomers and seasoned veterans keep their IPC-A-610 certification relevant.

All products on the assembly line undergo the same rigorous quality control checks as outlined in an IPC-A-610 training session. The process will decrease the time spent on rework and scrap, allowing manufacturing to go along more rapidly and saving money.

847-797-9250

847-797-9250