10 Advantages of Using a PCB Rework Stencil

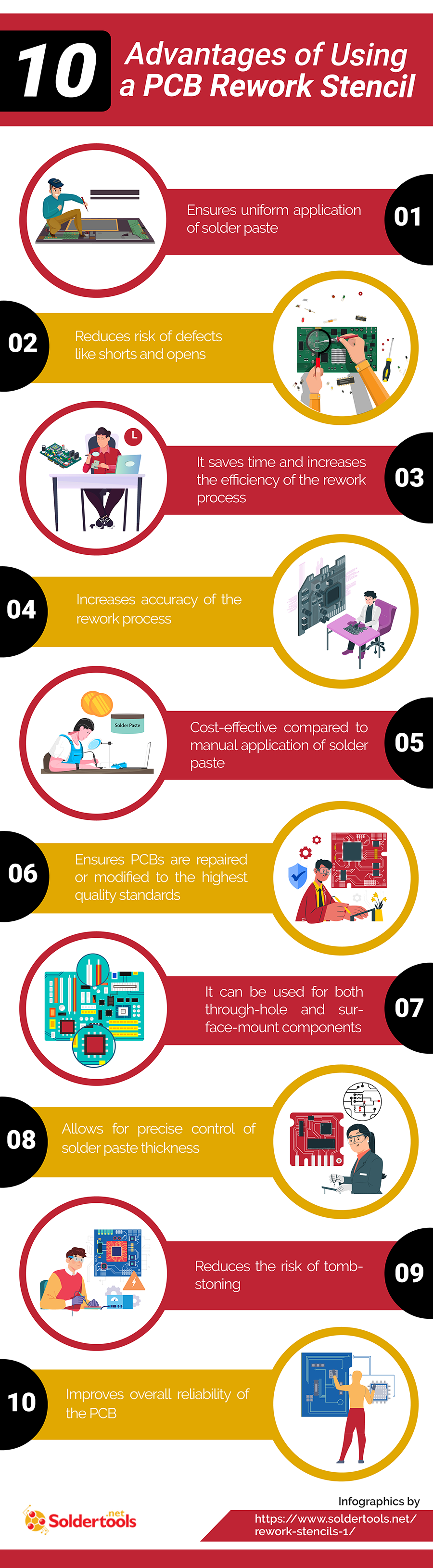

Printed Circuit Boards (PCBs) are essential components of electronic devices, and their flawless performance is crucial for the proper functioning of these devices. However, PCBs are susceptible to defects that can compromise their performance and render unusable. PCB rework is a process that involves repairing or modifying the PCBs to fix any defects that may have occurred during their manufacturing or use.

One critical component of the PCB rework process is the stencil. A PCB rework stencil is a thin, flat sheet of material made of stainless steel or polyimide that has a pattern of holes or apertures cut into it. These apertures correspond to the pads and vias on the PCB, and the stencil is used to apply solder paste to these areas during the rework process.

The solder paste is applied to the stencil using a squeegee, and excess paste is removed, leaving a precise amount of solder paste on the stencil's surface. The stencil is aligned with the PCB, and the solder paste is transferred to the PCB's surface through the apertures.

Using a stencil in PCB rework ensures that the correct amount of solder paste is applied uniformly to the PCB, reducing the risk of defects such as shorts, opens, and tombstoning. This makes the rework process more efficient, accurate, and cost-effective, ensuring that the PCBs are repaired or modified to the highest quality and performance standards.

847-797-9250

847-797-9250