Selecting the Appropriate BGA Reballing Stencil

Posted by Staff - Soldertraining on 30th Jun 2022

BGAs are a vital and intricate component of modern electronics. Thermal conductivity, package density, and resistance to interference are some of the features of most BGA packages. Thermal cycling or mechanical failures can lead to soldering problems between the component and the PCB .

Reballing is the best approach to repair BGA interconnection in this situation. The BGA rework stencil is a crucial tool for making the reballing process more efficient.

It’s necessary to reball the BGA after it has been taken from the PCB, and this is done with a hot air or IR rework station. The defective chip can be used again, or new balls can be transferred to a fresh component after it has been removed.

Types of BGA Stencils

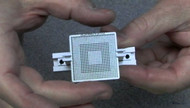

BGA stencils are constructed from stainless stell or plastic. Aperatures are laser cut into these thin materials. A BGA solder ball is sized to fit into each of the aperature as each of aperatures correspond to the pad pattern on the component. BGA stencils are custom fabricated to fit each of the thousands of different hole patterns.

Square matrices with identically sized holes make up universal stencils. They are great for reballing chips with the same ball diameter and pitch as the stencil.

Reballing kits usually come with universal stencils, which are ca then be customized by the user to fit the application.

BGA Reballing Stencils: What to Look for

When selecting BGA stencils, there are many essential things to bear in mind. The stencil’s resistance to distortion during heating is the first thing to take into account. Most computer chip reballing stencils are not heat-resistant; therefore, they should only be used for inserting the balls and removed when the chip is heated.

To ensure that the solder balls are correctly fastened, you must also know the BGA’s mechanical dimensions. The BGA’s overall size, pitch and number of IO are part of these sizing specifications.

What Is The Reballing Process For BGAs?

- When the solder reaches reflow temperature, lift the BGA from the PCB.

- Using a soldering iron, remove the solder balls from the attached board.

- Use isopropyl alcohol should be used to clean any flux residue from the printed circuit board.

Advantages of BGA Stencils

Reballing BGA stencils simplify and speed up the repair procedure. You can count on a low-cost repair procedure to deliver exact results even in narrow or oddly shaped spaces.

If your BGA stencil is the proper size, you’ll get better first-pass yields, better overall accuracy, and lower scrap costs when using that stencil. Additionally, the time necessary to align and position the gadget will decrease dramatically.