There are a variety of different materials which can be used for SMT prototype stencils. The most common materials include stainless steel and plastic. Stainless steel and the numerous alloys and derivatives of stainless are currently being used to fabricate SMT prototype stencils. They have very good heat withstand properties which is important as most of them are laser cut. The laser cutting is a heat generating process which can deform the apertures and cause “waves” underneath the stencil thereby having the past “smear” do to the lack of coplanarity. The stainless steel stencils also are very rigid and had and not prone to getting ripped as intensive pressure is applied to them as solder paste is rolled through the apertures of the stencil.

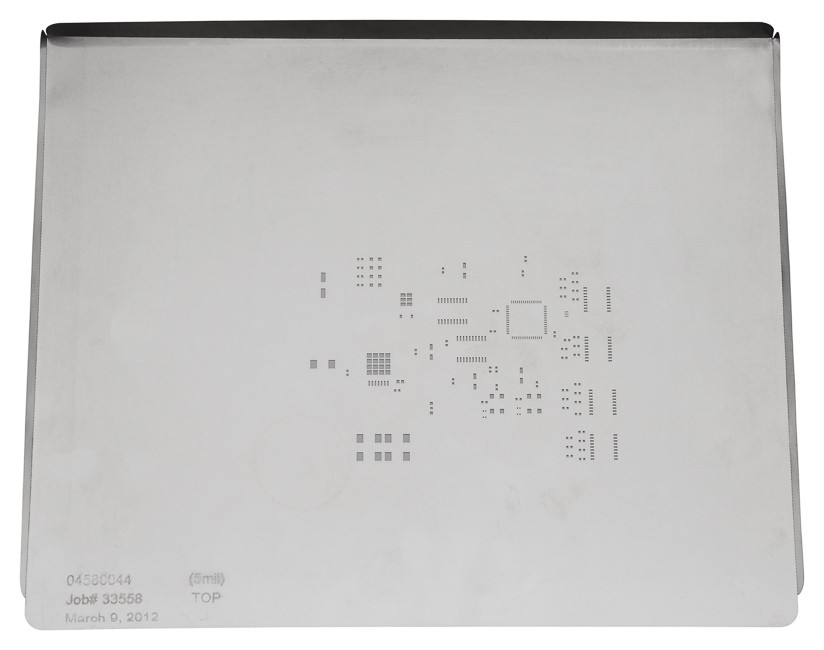

Stainless Steel Prototype Stencil

The other common materials SMT prototype stencils are made from are plastic films. The most commons films in use are Mylar and Kapton. The plastic film is much less expensive than the stainless steel, but it has limitations. These limitations include:

The lack of holding tension across the surface of the stencil thereby causing a lack of coplanarity with the board surface

The lack of heat withstand properties of the films as the heat generated by the laser cutting process causes the apertures and the film to be deformed

The lack of physical ruggedness and stability of the surface as the potential to tear it is there when the squeegee blade is dragged across the stencil

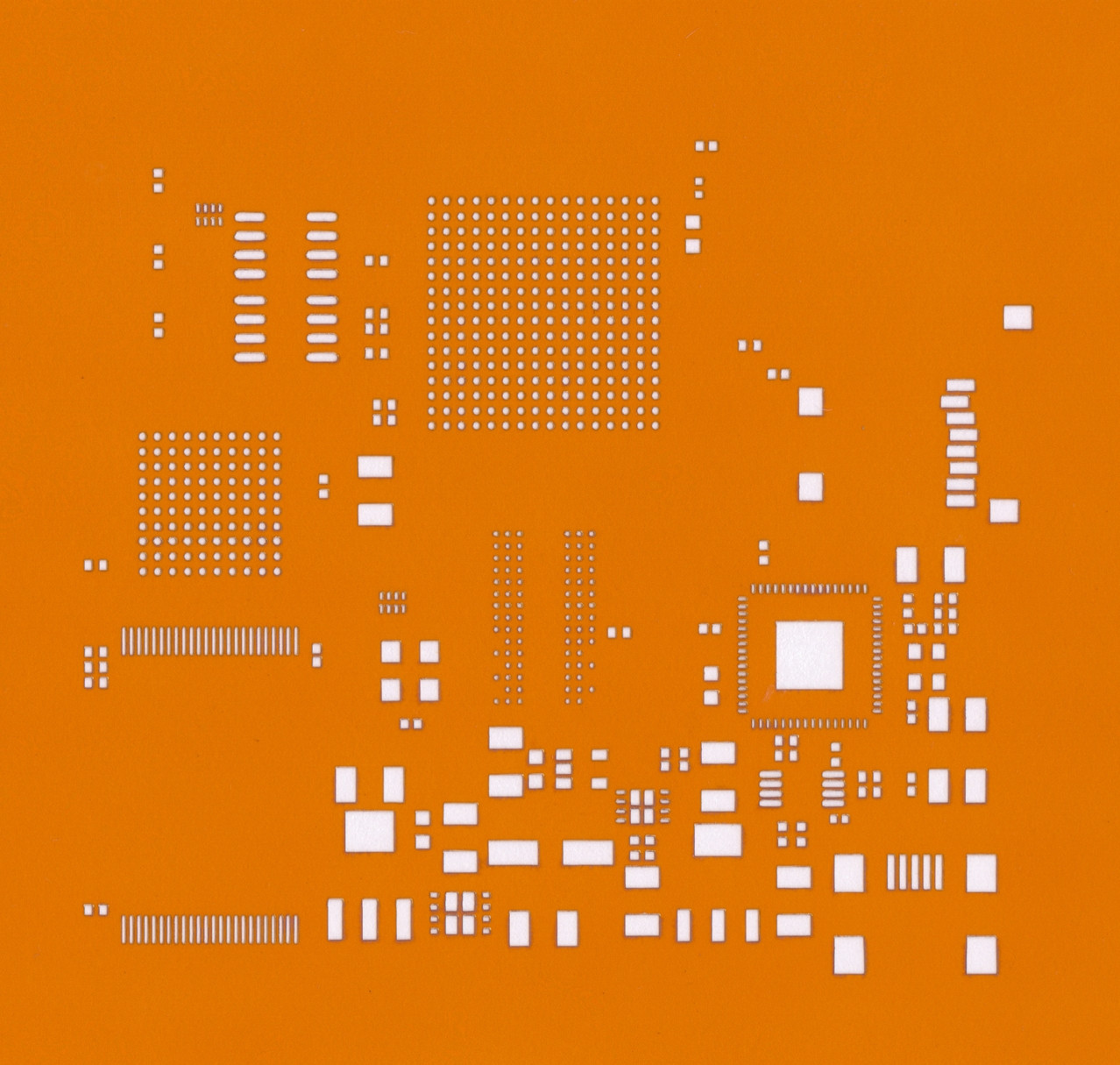

Kapton SMT Stencils

Kapton SMT stencils exhibit superior properties compared to Mylar as the Kapton has superior heat withstand properties. This means that when heated the material “buckles” near the aperture thereby causing solder paste to “leach” underneath the stencil during the printing process. In addition it makes the apertures “grow” in size. Kapton SMT stencils on the other hand can withstand the heat generated in the laser cutting process and thereby high quality print resolution is the outcome. Kapton SMT stencils have there place in low print volumes and older SMT technologies (moderate pitch, older psace/trace geometires)

Kapton(TM) SMT Stencil